BASF

Sustainable solutions for the footwear industry

Common goal

The collaboration between MASPICA SRL, owner of the Sixton Peak brand, and BASF, the world's largest chemical company, was created to give a strong signal towards the green transition by uniting two realities of excellence.

New innovative footwear lines

Sixton Peak's new HELEVO and DIVENTURE safety footwear collections represent a big step forward in the commitment to a more sustainable future, combining innovation and respect for the environment.

100% attributed recycled content

The soles of these shoes are made of BASF's dual-density Ccycled® polyurethane with 100% attributed recycled content by using the mass balance approach. For this innovative material, recycled raw materials that originate from used tires have replaced fossil raw materials by using BASF's ChemCycling® approach.

Innovation for safety and the environment

This choice represents a turning point in the safety footwear sector. BASF supports Sixton Peak, a benchmark in Italian safety footwear, in this technological and sustainable challenge.

Quality and sustainability without compromise

Sixton Peak shoes excel not only in their materials, but also in their environmental friendliness. By adopting the ChemCycling® process, the recovery and reuse of plastic waste such as tyres for disposal is promoted, reducing the use of fossil resources. All without compromising the quality of the end product, which keeps its properties intact.

Circular economy and sustainable innovation

This partnership represents Sixton Peak and BASF's commitment to a circular economy, giving new life to plastic waste and redefining the future of safety footwear.

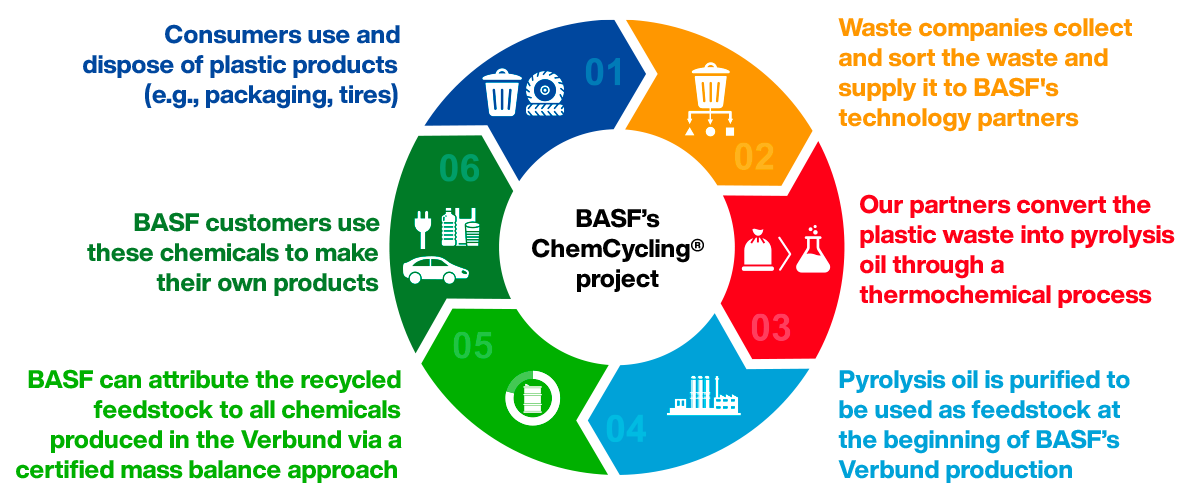

BASF’s ChemCycling®

Breaking new ground in plastics waste recycling

ChemCycling® helps save fossil resources and avoid emissions:

• CO2 emissions are avoided when plastic waste is chemically recycled compared to the incineration of plastic waste.

ChemCycling® turns plastic waste into virgin-grade high-performance products:

Using recycled feedstock from plastic waste in chemical production helps to replace primary fossil resources.

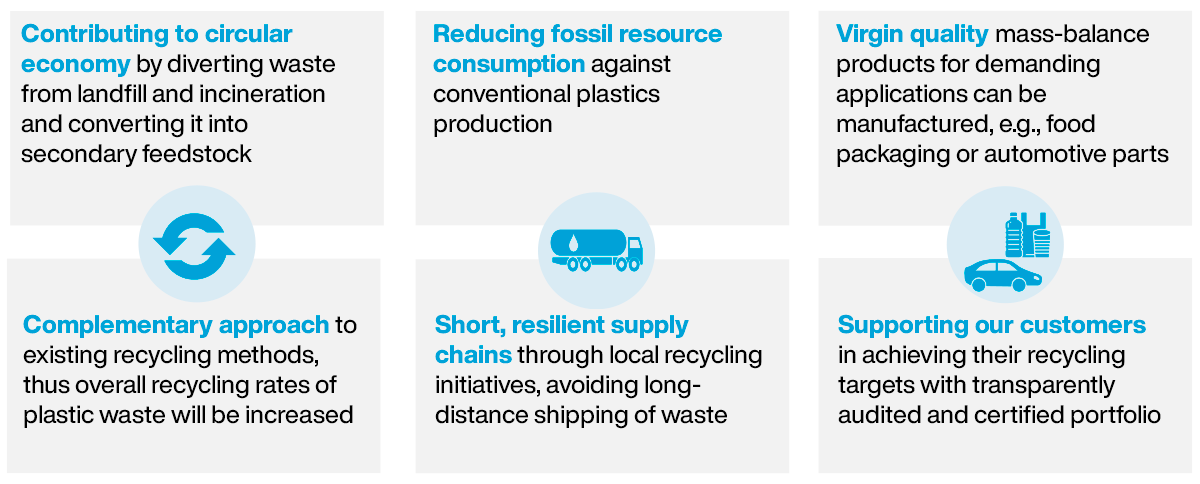

Benefits of ChemCycling® Overview

Why BASF is developing chemical recycling for use on industrial scale

What is the Mass Balance Approach?

Mass balance is a chain-of-custody approach to account for materials entering and leaving a system. Mass balance principles are recognized in the international standard ISO 22095:2020 and applied by various industries. In the chemical industry, renewable or recycled feedstock is mixed with conventional fossil feedstock in a continuously operating production process and attributed to the end products after chemical transformations have taken place. In order to use all possible feedstocks as efficiently as possible, a mass balance model with flexible feedstock selection is required.

Only raw materials used as feedstock, not for energy production, are considered for mass balance. Certification schemes define the rules for auditing and certifying that the substitution of fossil resources through recycled or bio-based feedstock is correctly accounted for. If customers decide to buy a product that offers a sustainability benefit while maintaining high quality, they can contribute to a higher proportion of alternative feedstock.

By using mass-balanced polyurethane from BASF in our footwear, Sixton Peak supports recycling of end-of-life tires.

Why the Mass Balance Approach?

An established method to foster sustainability in existing infrastructure

LIGHT SXT IN CCYCLED®

GREEN AND LIGHT GRIP-DESIGN

TRACTION TRIANGLES RELIEFS

UNDER YOUR FEET, SAFETY IS CERTIFIED