“Being so loved by our users and representing something personal for each of them, whether it is functionality, style or fit, makes us feel particularly responsible towards those who have always chosen us - says the chairman of Maspica Srl. Being in the everyday life of many people, knowing how to converse with everyone imposes an obligation on us to listen carefully to everyone's needs. The goal is not just comfort and well-being but bringing to life a unique experience of quality and value”.

With the University of Padua and other important partners, we have focused on the experience of the user who uses Sixton Peak® footwear, measuring live and in the laboratory the three parameters that best guarantee the well-being of the foot:

1. Energy absorption during impact, “Progressive Cushioning”

2. Foot stability on all types of surface, “Adaptive Stability”

3. Lifetime performance of the shoe, “Performance without expiration”.

After numerous tests made, in light of the excellent results of the individual surveys, it can be said that Sixton Peak® is authentically Move Safely!

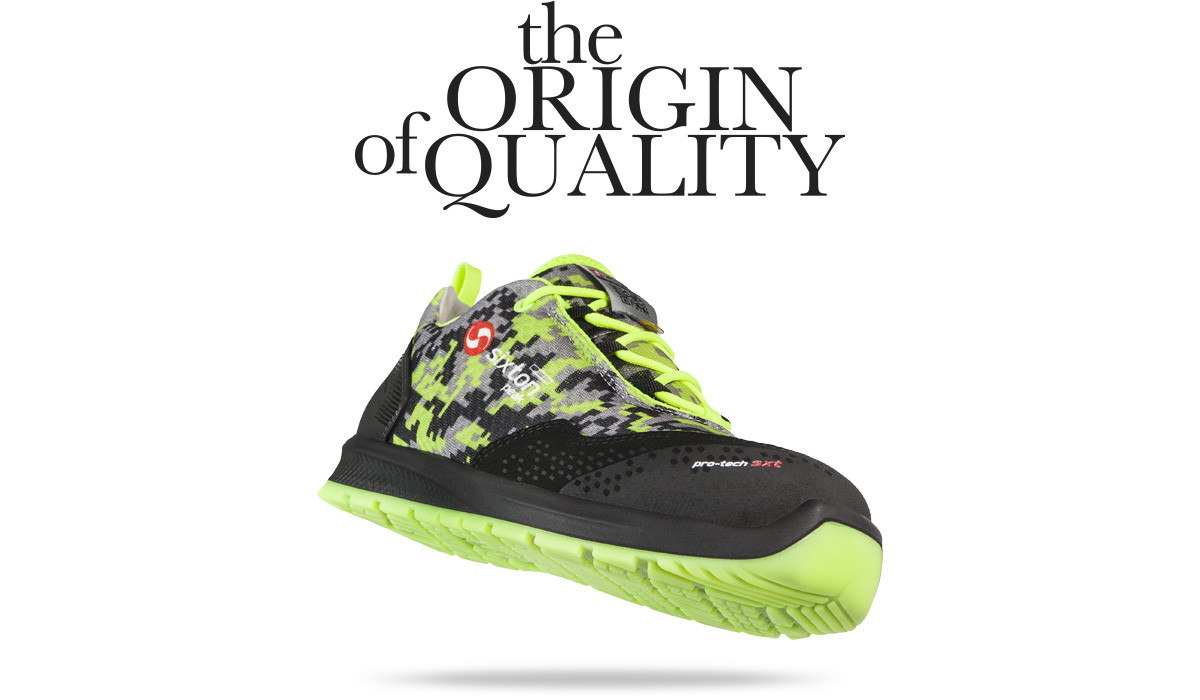

The Origin of Quality

The Sixton philosophy

The Sixton philosophy “The Origin of Quality Sixton Peak®” project, synonymous with safe, tested and certified quality.

The Origin of Quality at Sixton Peak® is a path of continuous transformation, a cultural change, a profound and strategic effect on the entire production process.

All Sixton Peak® safety footwear is accompanied by the brand-label, The Origin of Quality as a distinctive and tangible sign, which informs and draws the vision, gives life to a brand experience, that is to say the source, the origin of quality and the traceability of materials. Sixton Peak® has always kept the bar of total quality high, but it is through the story of the managers that one can discover the true meaning of this corporate value.

Quality is the protagonist across the board, a strong choice

Which combined with passion and determination, has required investments and continuous decisions that have allowed the company to create a real culture of quality, a global attitude that concerns not only research and innovation, style and selection of materials, but also the production cycle, the employees and the controls extended to all the processing phases. With this awareness everyone in Sixton Peak® believes in what he does and becomes important to the end user himself.

our philosophy

THE ORIGIN OF QUALITY

Wearing a Sixton Peak® shoe means feeling comfortable, moving freely and safely, ensuring controlled foot support, stable and comfortable movement of muscles and joints.

Just the attention to detail, the lengthy accumulated experience, care in sourcing the best raw materials allows us to create safety shoes of the highest quality.

Sixton Peak® is the certainty of having chosen the best.

OUR VISION

Being leaders in quality and innovation, putting users at the center of each of our projects. This means creating the best comfort for them, maximum safety and giving them a unique daily experience. It means ensuring a safe and comfortable work shoe, modern, but also good looking and endearing. Sixton Peak® means great quality for each worker, and being a high quality point of reference in the accident prevention sector.

OUR MISSION

Our feet are an important part of the body, they don’t just allow us to keep our balance and move, but they pick up a series of sensations that affect our well-being. Every day we work to create the best possible safety footwear and to offer the best service and the best "Move Safely" experience.

In the first place the well-being and the protection of the health of the worker.

“Our Total Quality is a concept that pervades all aspects of our daily actions and goes far beyond the process management for which Sixton Peak® acts in compliance with the EN ISO 9001, 14001, 45001 and SA 8000 certifications, also thanks to more than 30 tests carried out in the internal research laboratory, an accredited member, the first in Italy to the RPN inter-laboratory network (Ricotest Prociency Network). Sixton Peak® collaborates and confronts itself daily with the most authoritative certification bodies: Ricotest itself and then Satra, TUV, Cimac, CTC, CSA.

Here, however, people are equally important - both our human resources, who fully share the original vision of Maspica Srl and the Sixton Peak® brand, with a strong and cohesive team of engineers and technicians, determined to respect the mission and values of Sixton Peak® and to travel the path of continuous improvement - and our end customers, who entrust their well-being and the protection of their health to our footwear. We think of them at every moment, to the way in which we can better meet their needs with unique products, specially made for the most diverse and extreme work environments, always ensuring optimal solutions in terms of safety, comfort and style, the three pillars on which the global quality of our footwear is based, three assets of equal importance and always in perfect balance.

With this aim in mind, we maintain a continuous feed-back with the market, providing information and training but also with “one to one mentoring” with suppliers, wholesalers, retailers and consumers: it is a continuous exchange of opinions and skills that we consider extremely useful, to which we dedicate a lot of attention “.

The preparation of a virtuous chain, constantly monitored, finds concrete expression in footwear at the top of quality production.

“It all starts with rigorous checks and controls through physical and visual instrumental tests of incoming materials. The performance qualities and suitability for the intended uses of leather, fabrics and accessories, such as insoles, sheets and tips, are evaluated. In our factory, our highly qualified and experienced technicians are constantly present to check the quality of the various operations necessary to create the upper, from cutting to stitching up to assembly.

Each phase is supervised by the modeling technical office to make the employees aware of being part of the The Origin of Quality project, aimed at supremacy, excellence.

The Sixton Peak® shoe, before being placed on the market, is tested in the working environment to which it is designed to ensure “fitness for use”, its suitability for use. And so it is, that every finished product passes over 200 control operations to fully satisfy the strict EN ISO 20345: 2022 standards and presents itself as a leading article, made in a state of the art manner, able to offer maximum safety, superior resistance and absolute comfort.

The Sixton Peak® design is the universally recognized Italian style.

“Ours is the Italian style that takes its cue from dynamic concepts, which anticipate the rapidly changing market and is constantly evolving. We like to raise the level of the challenge, to go beyond what we have already seen, because we know that what satisfies us today will not do it tomorrow. It is a stimulating process to create, progress and innovate every day, to achieve at the same time concrete results that make Sixton Peak® footwear one of the most reliable in Europe ”.

Attention to the environment, sustainability as a strategic and responsible choice.

“Environmental protection is in the first place, as witnessed by the Sixton Peak® sustainability department for a production chain that aims to promote increasingly sustainable processes. So choice of materials with lower impact, more recyclable and biocompatible, and design of solutions that, for structure and workmanship, will not weigh on the environment. Not only that: we limit the consumption of raw materials, and any substance as much as possible, as well as we limit energy consumption, atmospheric emissions, packaging and noise pollution. We recover the leather, and textile based processing scraps, and put them into an upcycling process for a minimum waste of resources, trying to respect Mother Nature without compromise. For a sustainable evolution that goes to the Origin of Quality! “.